Index > Services > Honing Blocks |

![]()

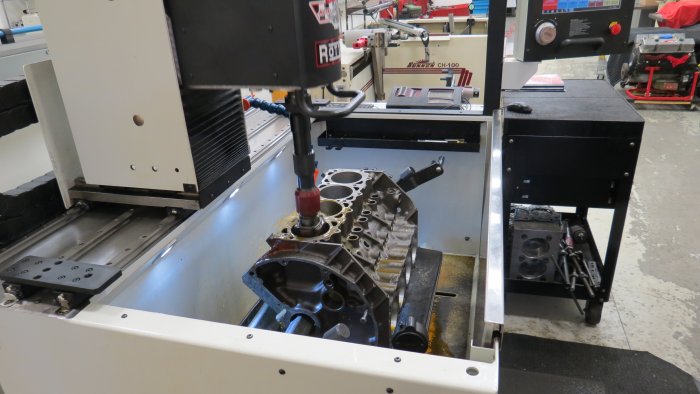

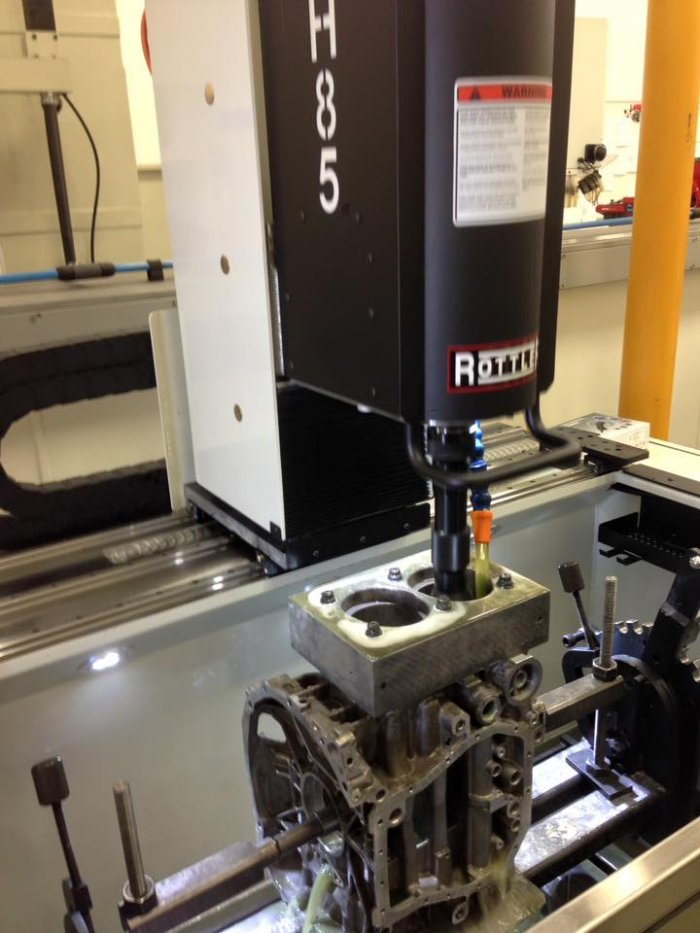

The new Rottler H85A

Rottler H85A CNC Diamond Hone honing a Subaru block

Rottler H85A CNC Automatic Vertical Honing Machine offers true, constant and accurate crosshatch angle the entire length of the bore with machine feeding stones to specified load during honing process and withdrawing stones before stopping. Rottler understands surface finish is critical and it can be hard to replicate consistently block after block. The Rottler H85A accomplishes this with extreme reliability

Standard Equipment

Automatic Lower Crash Protection System – every time cycle start is activated, the machine will check that the stones will not interfere with lower bore before starting rotation and stroking preventing stone and stone holder damage

.Spindle Taper with Quick Change System - change hone heads in seconds without any wrenches

Automatic Honing Stone retract at End of Cycle – the machine will automatically retract the stones during last stroke so that the stones do not leave any scratches or marks in the bore.

Automatic Cross Hatch Angle System – the machine will automatically adjust parameters to programmed cross hatch angle and finish the bore to programmed angle.

Automatic Roughing and Finishing Load Sensing System - machine short strokes or dwells anywhere it senses a tight area.

Automatic Stone Feed-out System - once hone head is positioned in the bore, the machine automatically expands stones and rotates slowly before starting hone cycle

Automatic Plateau Brush Finish Program - the machine automatically expands plateau brushes to programmed load and counts down number of plateau strokes, then withdraws the brushes and retracts to the clearance position.

- Control and programming through 15" (400mm) CNC Touch Screen Control

- Precision Display in .0001" (.002mm) resolution

- Industrial PC with Windows Operating System

- USB Flash Drive and port for file transfer

- Horizontal Movement (X Axis) - Left and Right Direction - 38" (965mm) - movement is manually on linear slideways

- Horizontal Movement (Y Axis) - Front and Back Direction - 3" (75mm) - movement is manually on linear slideways

- Vertical Movement (Z Axis) - Up and Down - 19" (483mm)

- Stroking System - CNC SERVO Controlled High Pitch Ball Screw System

- Infinitely Variable Stroke Speed Control - Variable from 0 to 1500IPM (38m/min)

- Rapid Stroke System Acceleration - 250in/sec (6.35m/sec)

- Spindle Rotation System - CNC SERVO Controlled High Torque Spindle Rotation System - 44 ft.lbs (60NM)

- Infinitely Variable Spindle RPM Control - Variable from 0 to 400RPM

- (2) Stone Trays for up to 6 stone holder sets with built-in Dial Bore Gage Holder

- Hone Head Storage Rack for up to 5 Hone Heads

- Coolant System - Large Capacity coolant tank 70 Gal (265 Liter) - tank is located under the machine on wheels and is removable for servicing from front or rear of machine

- Magnetic system for primary filtering inside coolant tank. Magnets are removable for easy tank cleaning once tank is removed from under the machine

- Replacable Cartridge Canister Filter System. Dual Gradient 50-5 Micron replacement filter cartridge keeps coolant and cabinet clean. Filter Cartridge 514-2-42C